Compressed Air Storage Strategies

Compressed air storage can allow a compressed air system to meet its peak demand needs and help control system pressure without starting additional compressors. The appropriate type and quantity of air storage depends on air demand patterns, air quantity and quality required, and the compressor and type of controls being used. An optimal air storage strategy will enable a compressed air system to provide enough air to satisfy temporary air demand events while minimizing compressor use and pressure.

The use of air receivers is especially effective for systems with shifting air demand patterns. When air demand patterns are variable, a large air receiver can provide enough stored air so that a system can be served by a small compressor and can allow the capacity control system to operate more effectively. For systems having a compressor operating in modulation to support intermittent demand events, storage may allow such a compressor to be turned off. By preventing pressure decay due to demand events, storage can protect critical end-use applications and prevent addi-tional units from coming online.

Air entering a storage receiver needs to be at a higher pressure level than the system pressure. A good air storage strategy will allow the differential between these two pressure levels to be sustained. To accomplish such a pressure differential, two types of devices can be employed: Pressure/Flow Controllers (P/FC) and metering valves.

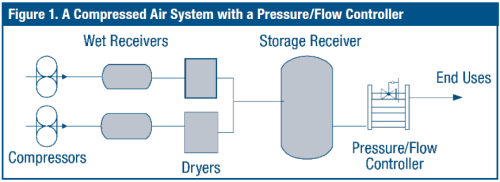

A P/FC is a device that serves to separate the supply side of a compressed air system from the demand side. In a system that employs P/FCs, the compressors generally operate at or near design discharge pressure to ensure that the P/FC receives air at a higher pressure level than it will discharge into the system. This allows the pressure in the demand side to be reduced to a stable level that minimizes actual compressed air consumption. P/FCs are added after the primary receiver to maintain a reduced and relatively constant system pressure at points of use, while allowing the compressor controls to function in the most efficient control mode and discharge pressure range. Properly applied, a P/FC can yield significant energy savings in a system with a variable demand load. See Figure 1.

For situations in which just one or a few applications have intermittent air demand, a correctly-sized storage receiver close to the point of the intermittent demand with a check valve and a metering valve can be an effective and lower cost alternative. For this type of storage strategy, a check valve and a tapered plug or needle valve are installed upstream of the receiver. The check valve will maintain receiver pressure at the maximum system pressure; the plug or needle valve will meter the flow of compressed air to “slow fill” the receiver during the interval between demand events. This will have the effect of reducing the large intermittent requirement into a much smaller average demand. See Figure 2.

The use of air receivers is especially effective for systems with shifting air demand patterns. When air demand patterns are variable, a large air receiver can provide enough stored air so that a system can be served by a small compressor and can allow the capacity control system to operate more effectively. For systems having a compressor operating in modulation to support intermittent demand events, storage may allow such a compressor to be turned off. By preventing pressure decay due to demand events, storage can protect critical end-use applications and prevent addi-tional units from coming online.

Air entering a storage receiver needs to be at a higher pressure level than the system pressure. A good air storage strategy will allow the differential between these two pressure levels to be sustained. To accomplish such a pressure differential, two types of devices can be employed: Pressure/Flow Controllers (P/FC) and metering valves.

A P/FC is a device that serves to separate the supply side of a compressed air system from the demand side. In a system that employs P/FCs, the compressors generally operate at or near design discharge pressure to ensure that the P/FC receives air at a higher pressure level than it will discharge into the system. This allows the pressure in the demand side to be reduced to a stable level that minimizes actual compressed air consumption. P/FCs are added after the primary receiver to maintain a reduced and relatively constant system pressure at points of use, while allowing the compressor controls to function in the most efficient control mode and discharge pressure range. Properly applied, a P/FC can yield significant energy savings in a system with a variable demand load. See Figure 1.

For situations in which just one or a few applications have intermittent air demand, a correctly-sized storage receiver close to the point of the intermittent demand with a check valve and a metering valve can be an effective and lower cost alternative. For this type of storage strategy, a check valve and a tapered plug or needle valve are installed upstream of the receiver. The check valve will maintain receiver pressure at the maximum system pressure; the plug or needle valve will meter the flow of compressed air to “slow fill” the receiver during the interval between demand events. This will have the effect of reducing the large intermittent requirement into a much smaller average demand. See Figure 2.

Comments